Process & Power Boilers

Ankur Scientific has a long experience in designing Boilers and getting the same manufactured to the best world standards. Listed below are the strengths we bring to the table:

- Mechanical Design as per ASME SECTION 1 or IBR or any required code under third party inspection (like Bureau Veritas or TUV).

- Manufacturing, Testing & Inspection as per IBR, ASME or under best Engineering practice.

- Material as per ASTM/DIN/IS/BS standards

- Special designs available for Jute bags, Cloth, Low Calorific Value Biomass, High Moisture Biomass (Up to 60%)

- Choice & Selection of different grates like Fluidised, Bubbling, Reciprocating or Travelling grate

- Highest Combustion Efficiency and overall Efficiency of the Boiler

- In-house Thermal design and Heat Transfer area calculation based on latest Engineering practice, performance and formulae.

- Distribution of Heat transfer area & fixing boiler geometry & construction based on nature of fuel.

- Automation & no back-fire

- No black or white smoke in chimney

- SPM, SOX, NOX in line with local pollution control board norms

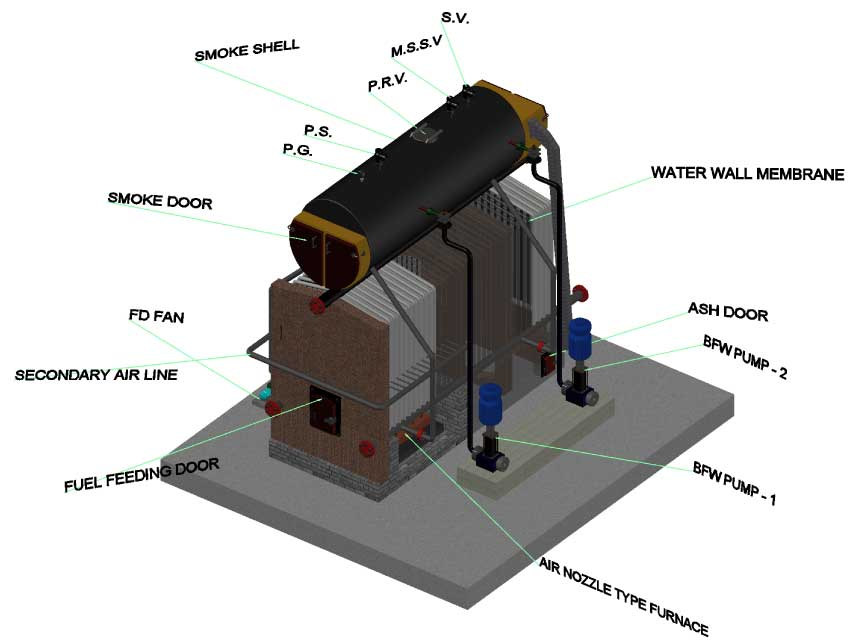

- Hybrid (Smoke-cum-water tube) and 100% water tube boilers

- Customised 3/4/5 pass designs

- Minimum refractories and onsite work. Pre-fabricated modules up to 3 TPH

- Minimum foundations

- Range : 0.5 TPH to 5 TPH (Process boilers)

BTG PACKAGE

Following Services / Features are offered:

- Design, Engineering, Supply, Installation & Commissioning of Boiler-Turbine-Generator package

- Selection of most efficient operating condition

- Boilers as per ASME or IBR.

- CE certified Turbines

- Boiler-Turbine integration and stress test

- Air cooled condensers for countries having cold climate

- Lower foot-print

- Supplied with 2 years recommended spares

- Easy to operate

- PLF more than 90%

Ankur Scientific has a long experience in designing Boilers and getting the same manufactured to the best world standards. Listed below are the strengths we bring to the table:

- Mechanical Design as per ASME SECTION 1 or IBR or any required code under third party inspection (like Bureau Veritas or TUV).

- Manufacturing, Testing & Inspection as per IBR, ASME or under best Engineering practice.

- Material as per ASTM/DIN/IS/BS standards

- Special designs available for Jute bags, Cloth, Low Calorific Value Biomass, High Moisture Biomass (Up to 60%)

- Choice & Selection of different grates like Fluidised, Bubbling, Reciprocating or Travelling grate

- Highest Combustion Efficiency and overall Efficiency of the Boiler

- In-house Thermal design and Heat Transfer area calculation based on latest Engineering practice, performance and formulae.

- Distribution of Heat transfer area & fixing boiler geometry & construction based on nature of fuel.